Which CastorCrete System is Right For You?

There are a lot of options to consider when selecting flooring. Narrowing it down to a liquid applied or poured in place system may lessen the options, however, not all of these systems are appropriate in food and beverage manufacturing facilities. Specifically, the use of low-cost, general-purpose resins that do not have the chemical resistance to withstand the animal fats, caustic cleaners and strong acids will cause failures.

CastorCrete offers a variety of system options, but which one is right for you?

CastorCrete polyurethane cementitious mortar systems are engineered to perform under the harshest environmental conditions providing monolithic solutions that are hygienic, durable and safe to work on.

Benefits of a CastorCrete System

There are several benefits to choosing a CastorCrete System for your facility.

- Industrial grade

- More effective for cleaning and sanitation by design

- Resistant to heavy load traffic

- Resistant to thermal shock

- Resistant to thermal cycling

- Tolerant to moisture

- Excellent impact resistance

- Resistant to salts, fats, organic acids, sanitizers and other harsh chemicals

- Installed in both wet and dry exposures

- Designed for various thicknesses

- Over 50 finish and color selections

- Quick installation eliminates downtime

Hygienic

CastorCrete mortars are industrial grade, poured in place polyurethane cement mortar systems that are monolithic and non-absorbent. This eliminates seams and cracking which allows for more effective cleaning and sanitation that is consistent with FDA, USDA and HACCP inspected facilities.

Durability

Resistant to heavy load traffic, thermal shock and thermal cycling, CastorCrete mortars are tolerant to moisture inherent in the substrate, providing excellent impact resistance. CastorCrete products by composition are resistant to salts, fats, organic acids, sanitizers and other harsh chemicals.

Safety

CastorCrete Systems can be installed to meet EHS and texture requirements in both wet and dry exposures – ensuring safe working conditions for employees, customers and visitor in any facility or space.

Design Flexibility

CastorCrete Systems can be designed to various thicknesses depending on work load and budget. These systems offer over 50 different finish and color selections utilizing our vast line of coatings options, colored vinyl flakes and decorative quartz broadcasts. Mortars cure rapidly, eliminating downtime and making for faster installations.

Typical Installations

Light & Medium Duty Systems

- Cafeterias and break rooms

- Restrooms and locker areas

- Laboratory spaces

- Corridors

- Commercial kitchens

- Educational facilities

- Veterinary clinics

- Animal holding

- Vivariums

- Pharmaceutical facilities

Heavy Duty Systems

- Food & beverage production facilities

- Chemical processing facilities

- Heavy manufacturing

- Water treatment plants

- Vehicle & aircraft maintenance facilities

- Loading docks

Which System is Right for Your Project?

CastorCrete System Selections

CastorCrete offers three base mortar options that provide the cornerstone of proper system design and selection.

Light To Heavy Load Systems

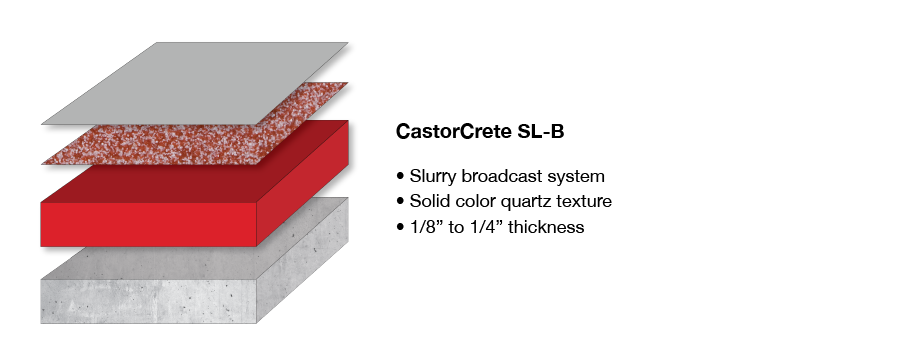

CastorCrete SL-B

This CastorCrete system is a slurry broadcast system that is offered in solid color quartz texture and sealed with a solid colored epoxy or polyurethane topcoat. Installed between 1/8″ to 1/4″ thicknesses.

CastorCrete Bio-Floor

CastorCrete Bio-Floor is a slurry mortar with a decorative flake or decorative quartz finish – typically sealed with a grout coat of epoxy and topcoat of polyurethane clear or single topcoat of polyaspartic clear and installed between 1/8″ to 1/4″ thicknesses.

CastorCrete SL-CQ

This slurry broadcast system uses decorative colored quartz in a double broadcast application. This ensures even color, texture and an increased durability. This system is sealed with a clear epoxy or polyurethane topcoat and installed between 3/16″ to 3/8″ thickness.

Medium To Heavy Load Systems

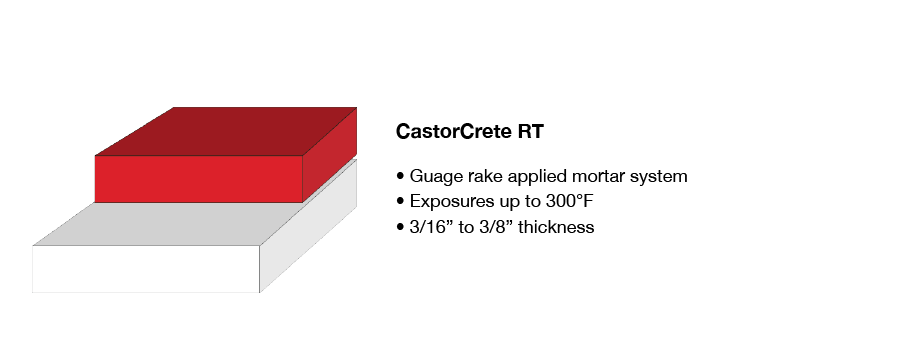

CastorCrete RT

CastorCrete RT is a gauge rake applied mortar system used as a resurfacer with a smooth finish. This system is meant for exposures up to 300F and installed between 3/16″ to 3/8″ thickness.

CastorCrete RT-B

This gauge rake applied mortar system is used as a resurfacer. CastorCrete RT-B is offered in a solid color quartz broadcast texture and sealed with a solid colored epoxy or polyurethane topcoat. Installed between 3/16″ to 3/8″ thicknesses.

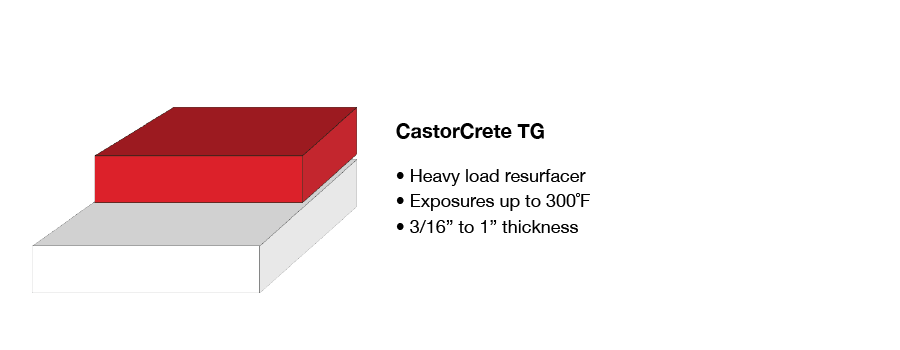

CastorCrete TG

Trowel applied, this system is a heavy load resurfacer with an inherent consistent texture for exposures up to 300F. Installed between 3/16″ and 1″ thicknesses.

CastorCrete TC UV

CastorCrete TC UV is an aliphatic polyurethane cementitious topcoat loaded with aluminum oxide. This ultraviolet light resistant top coat is used over CastorCrete polyurethane cementitious mortar systems. This top coat is slip-resistant and durable. CastorCrete mortar products without a protective top coat will undergo ultraviolet light induced discoloration, but they will not degrade.

Still not sure which CastorCrete system is best for you? Contact your local sales rep for more information.